AI applications in storage and inventory management

Stock Management

Use DENKnet for logistics, tracking and inventory. Reliable visual inventory & object recognition.

Inventory Management

Inventory management through AI-based image analysis enables efficient and automatic tracking of stock without manual effort. The AI can recognize various objects, count them, and determine their position, simplifying stock management and control while increasing accuracy. Enormous efficiency gains can be achieved, for example, with drones equipped with AI-based image analysis: rapid inventory capture, especially in hard-to-reach high-bay warehouses. For managing stock in the manufacturing process, workpieces or components can be captured directly on production lines. This prevents bottlenecks in production and ensures a continuous flow of materials. The capture of medical devices and consumables in storage rooms or pharmacies allows for automated inventory management in healthcare.

Depending on the task, realisable with the following technologies:

- Object detection

- Instance Segmentation

- OCR (Character and text recognition)

Example industries: Manufacturing, automotive industry, logistics, medical technology, packaging industry, retail

Discuss your use case

Counting

Counting objects and stock through AI-based image analysis plays a key role in warehouse and inventory management, as it speeds up processes, minimizes errors, and increases efficiency. The AI recognizes and counts various objects in real-time, allowing for precise stock monitoring. Whether perishable raw materials like fruits and vegetables or components of any material, the AI enables accurate counting for goods receipt inspections or packaging quantities.

Depending on the task, realisable with the following technologies:

- Object detection

- Instance Segmentation

Example industries: Logistics, food industry, manufacturing, automotive industry, medical technology, packaging industry, retail, pharmaceutical industry

Discuss your use casePositioning

Positioning through AI image analysis is crucial for precise warehouse and inventory management, as it detects and tracks the exact location of products or materials in a warehouse or production facility. Warehouse location recognition and assignment, automated navigation for warehouse robots, real-time position monitoring during goods receipt inspection, and more can be reliably implemented.

Depending on the task, realisable with the following technologies:

- Object detection

- Instance Segmentation

Example industries: Logistics, manufacturing, automotive industry, medical technology, packaging industry, retail

Discuss your use case

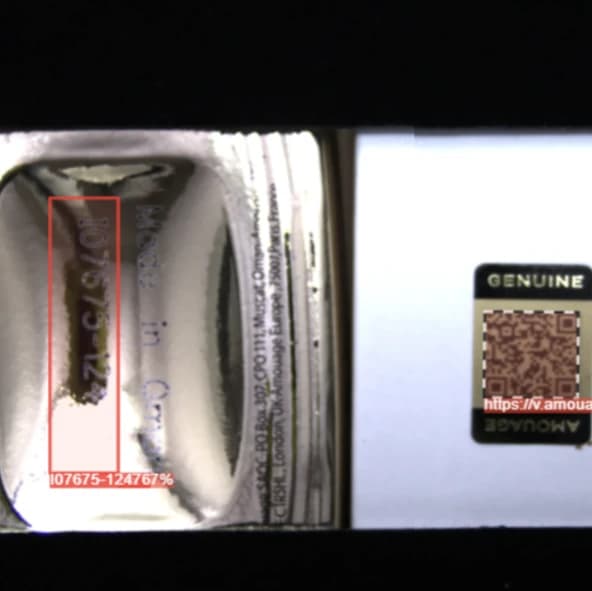

Tracking

Tracking goods, materials, or stock through AI image analysis plays a central role in warehouse and inventory management to create transparency over movements and locations. It allows real-time monitoring of the whereabouts of items and optimizes warehouse processes. Visual tracking enables real-time tracking of where specific items are, reducing stockouts or search times. During goods receipt and dispatch, the AI automatically identifies and documents the movement of items, pallets, and containers.

Depending on the task, realisable with the following technologies:

- Object detection

- Instance Segmentation

- OCR (Character and text recognition)

Example industries: Logistics, manufacturing, automotive industry, medical technology, packaging industry, retail

Discuss your use case