Our Technology for Your Production

The B-Integrate is our solution for professional and reliable use in production environments. Whether for quality control or integration into products – the B-Integrate can be used flexibly and is specifically designed for device manufacturers and integrators.

Opportunities with Magnetic Field Measurement

Be one step ahead of your competitors

Our B-Integrate can be easily and flexibly integrated into manufacturing processes or products. Optimized for integrators and device manufacturers for quality control or expanding their own service portfolio.

- Meets Industry Standards

Developed and manufactured with a focus on reliability and usability.

- Easily Integrable

Mechanical and software integration tested and stable.

- Clear Results

AI-based evaluation with clear results. Everything from a single source.

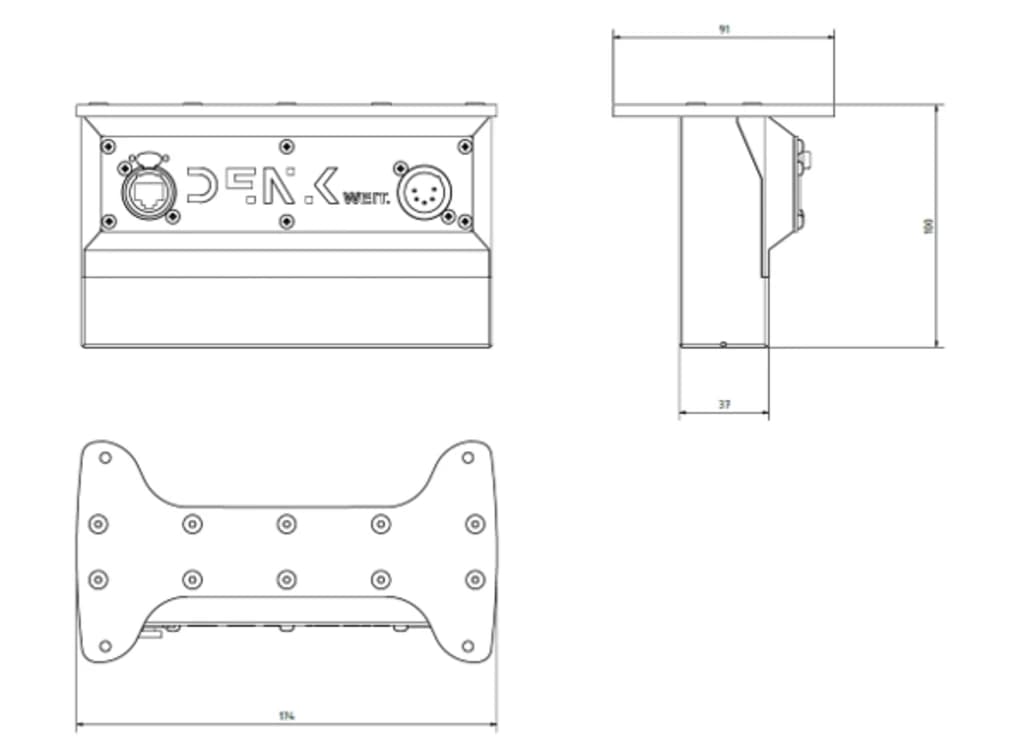

Technical Specifications

With our patented Fraunhofer technology, you can non-destructively and safely measure the surface distribution of the direction and strength of electrical currents within seconds.

- Measurement range of magnetic flux density B: ±1.3 mT (x, y), ±2.5 mT (z)

- Resolution: 0.3 µT, Sensor width: 160 mm

- Sampling rate: approx. 30 Hz

- Interface to PC: Ethernet

- Power supply: 5 - 9 V DC / 3 A or 18 - 30 V DC / 1.5 A

- Dimensions: 174 x 91 x 100 mm

- Weight: approx. 700 g