Food Industry

The food industry encompasses the production, processing, packaging, and distribution of food and beverages. Food manufacturers should use Vision AI to ensure the quality and safety of their products, increase the efficiency of their production processes, and improve regulatory compliance. Vision AI can automatically perform quality controls by identifying defective or contaminated products, ensuring consistency in size and shape, and detecting foreign bodies or contaminants. Additionally, Vision AI supports the optimization of packaging processes and reduces waste through precise monitoring and real-time error detection.

Contact UsForeign Particle Detection

Using Vision AI, foreign particles on, in, or between food items can be identified in real-time. Unwanted materials (glass, metal, wood, stones, organic foreign bodies, etc.) can be detected and classified. These automated visual inspections can be carried out on both unpackaged and (semi-)transparently packaged foods. When high-resolution cameras are used, even small particles can be detected.

- Protection of end consumers and fewer recalls.

- Market trust through enhanced product safety.

- Efficiency gains through faster inspection of large batches.

- Compliance with regulatory standards according to legal requirements.

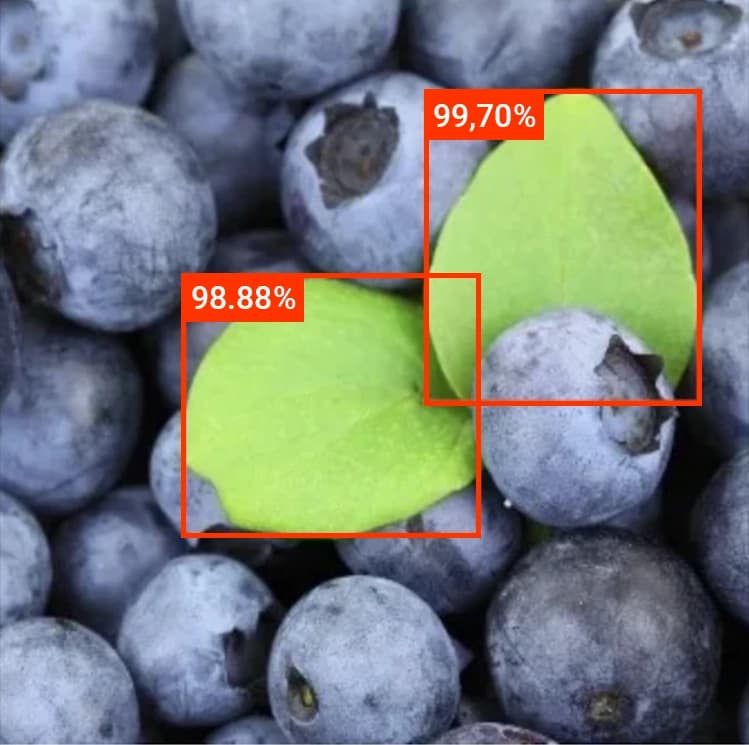

Sorting Processes

By using advanced image processing technologies, food can be precisely sorted by size, shape, color, and quality. This enables, for example, early sorting out of inferior or damaged products and ensures that only high-quality goods leave the production line. Reliable sorting by ripeness levels, deformations, or individual criteria is possible. This not only reduces waste but also improves the consistency and quality of end products.

- Reduced misallocations even at high throughput.

- High processing speed of sorting processes.

- Flexible adaptability to sorting criteria.

Inspection of Labels and Expiration Dates

In the food industry, label accuracy is crucial to ensure that all information is correct and compliant with regulations. Vision AI helps to check labels quickly and accurately by detecting errors such as incorrect ingredient lists, faulty best-before dates, or wrong allergy warnings. By using Vision AI, companies can ensure that all labels meet high quality standards and provide consumers with accurate information. This minimizes the risk of costly recalls while protecting customer trust in the brand.

- Error-free quality controls.

- Increased output through continuous real-time inspection.

- Compliance with legal regulations and fewer recalls.

Packaging and Warehousing

Complete and legible labels and markings are important for traceable production, inventory monitoring, optimized storage capacities, and customer satisfaction. However, undamaged and complete packaging is also essential for safe food. With image processing AI, all processes can be monitored and automated.

- Avoidance of recalls through error-free packaging and safe food.

- Reduction of downtime and production losses.

- Product tracking and transparency.

DENK Facts

What DENKweit Offers You

DENKnets: Proprietary unique AI technologies that detect everything.

- Use without AI experts

The intuitive no-code platform DENK VISION AI Hub enables AI training that anyone can perform.

- No preparation necessary

No adjustments to your images or on-site conditions are needed for AI deployment.

- Stable AI that detects everything

DENKnets were developed for production environments and changing conditions and detect everything a human can see.