Less waste, higher quality, safer solar modules.

Photovoltaics is a key industry for the energy transition, where reliable solar modules are essential. High cost pressure and new technologies such as shingle modules place the highest demands on quality inspection. Our non-destructive measurement methods ensure efficient inspection of various components. Stay ahead. Higher quality means less waste and safer solar modules.

B-Tech Facts

Precision that redefines quality in the solar industry.

Increase production and reduce costs with innovative sensor technology.

- Optimization of Production Quality

B-TECH enables precise real-time monitoring of critical production processes, such as automated soldering procedures, to detect errors at an early stage.

- Seamless Integration

B-TECH can be easily integrated into automated processes without disrupting the workflow.

- Reduction of Waste

The highly precise inspection prevents production errors and minimizes material losses, increasing the efficiency and cost-effectiveness of production.

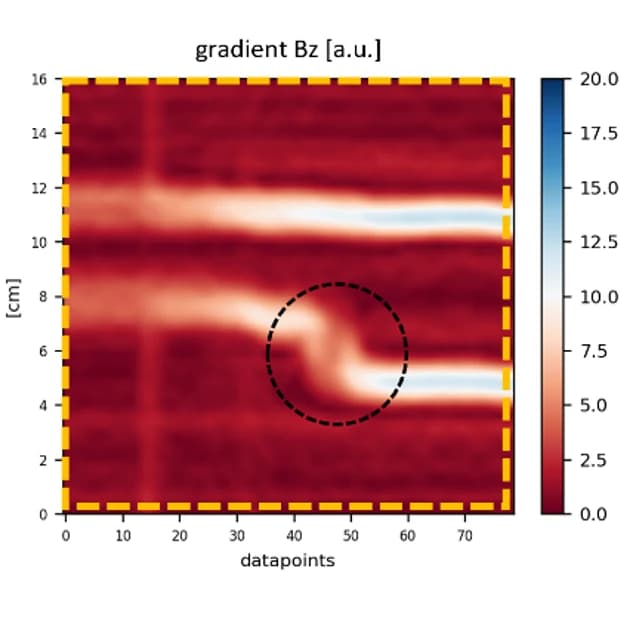

Quantitative Testing of Cross and Cell Connectors

Eliminate uncertainties in detecting defective cross and cell connectors with our innovative B-TECH technology. Quickly determine the cause of lower efficiencies and higher series resistance in your solar modules. Whether in production, in a solar park, or in the laboratory, our product portfolio offers the perfect solution for all your needs.

- Non-destructive inspection of all solder joints

- Meets all production cycle times

- Quantitative assessment of soldering processes

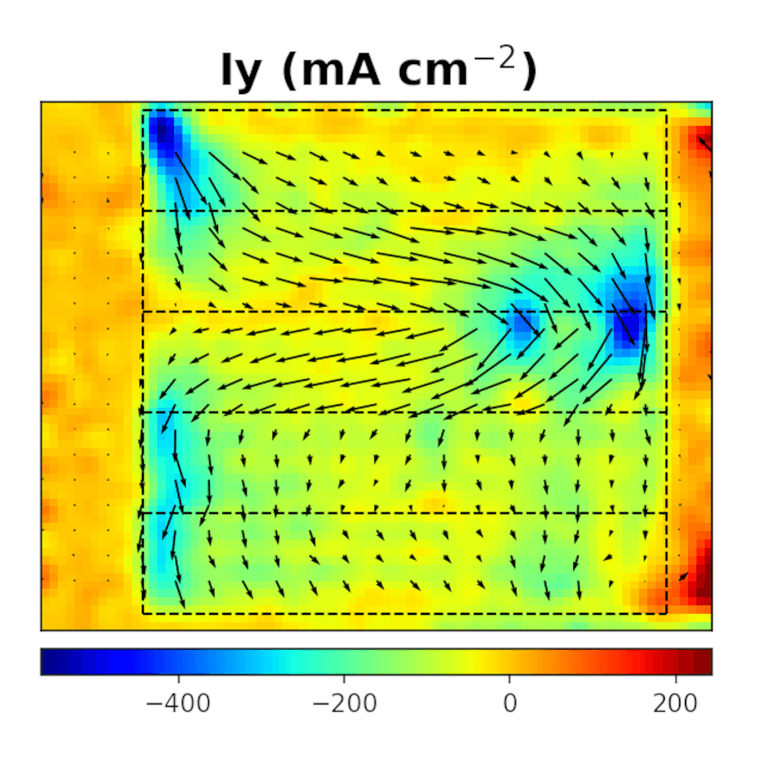

The Perfect Inspection for Shingle Modules

Our technology can revolutionize your shingle module inspection. With B-TECH, current flows through complex structures can be analyzed in detail. Our solution enables the identification of defective adhesive joints and optimization of the matrix layout by visualizing electrical current under partial shading. The possibilities are limitless. A must-have for shingle production.

- Visualization of current distribution in the module

- Easy integration into the production process

- Unprecedented depth of information for shingle modules

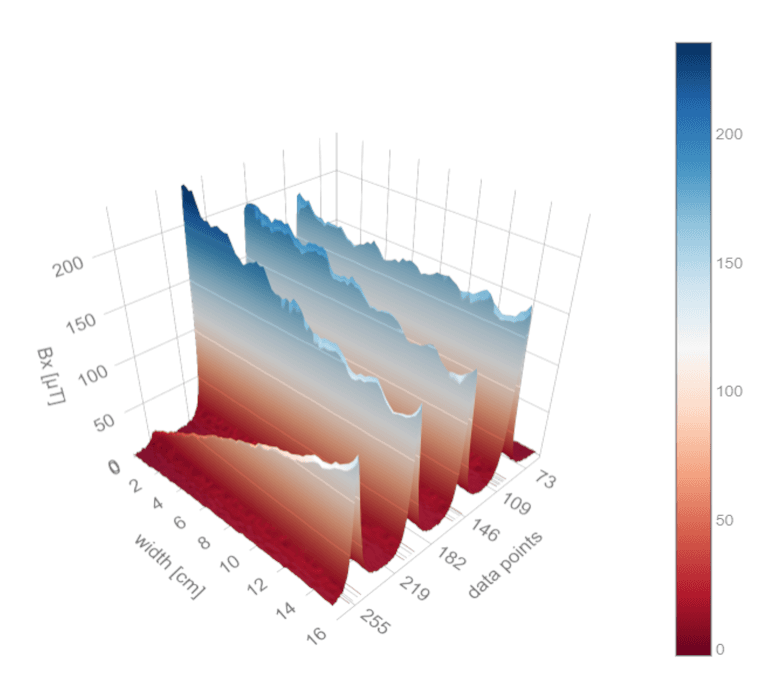

Testing the Bypass Diode

With B-TECH, you can easily detect defective bypass diodes in junction boxes, even if they are encapsulated and inaccessible for direct electrical examination. Our technology allows diode analysis in the solar park during operation and identifies both short-circuited and interrupted diodes for fast and efficient maintenance and repair. We are currently working on integrating the technology into production.

- Testing the functionality of diodes in the field by simple placement

- Clear and quantitative statement on the diode's blocking quality

- Non-destructive real-time analyses