Author: REC Solar Holdings

Advanced EL Testing at REC Solar Holdings

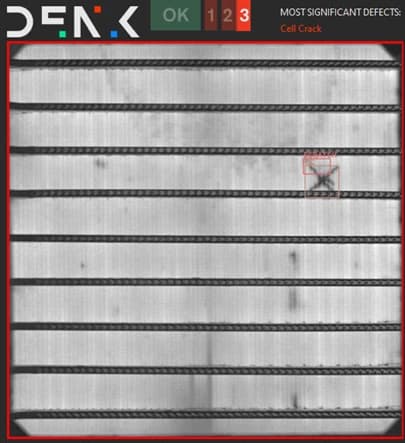

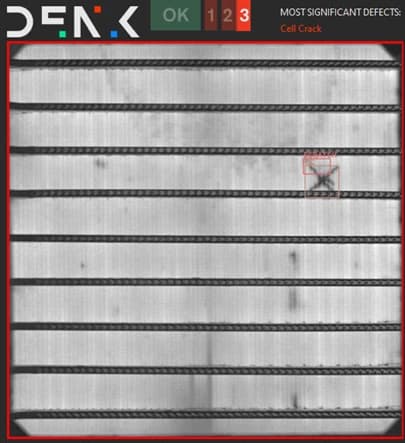

Revolutionising the quality assurance of solar cells: Maximum precision in the quality assurance process using DENK EL analysis software.

Leading solar technology

DENKnet: Part of our success story

At REC, our commitment to excellence in solar cell manufacturing drives us to continuously innovate and improve our processes. Recently, we achieved a significant milestone by upgrading our Electroluminescence (EL) testing system, a crucial step in ensuring the highest standards of quality in our solar cells. By implementing Denkweit’s AI-based image evaluation software, we have not only streamlined our quality assurance processes but also dramatically enhanced the accuracy and precision of defect detection.

Goal: Analysing processes in real time

The Challenge

Our previous EL testing system served us well in detecting and categorizing defects such as print defects, scratches, dark area, and cross cracks. However, the system was limited in its functionality, offering a binary classification of cells as either "good" or "bad." This limited the depth of analysis and required additional manual inspections for further defect evaluation. Although the system could link results to a database, the analysis process was time-intensive and did not effectively leverage historical data for ongoing quality improvement.

The solution

To address these challenges, we integrated Denkweit`s AI-based EL image evaluation software into our operations. This integration has revolutionized our quality assurance process:

1. Customizable Classification:

Unlike the rigid classifications of our previous system, Denkweit's software allows us to define classifications based on our specific needs. This flexibility enables us to categorize cells into nuanced groups, depending on the severity and type of defects.

2. Superior Defect Detection:

The AI-driven detection system has substantially enhanced our ability to detect defects. By providing highly accurate and reliable evaluations across a wide range of defect classes, the software ensures that our quality control process is both thorough and precise.

3. Automated and Enhanced Analysis:

The results from the EL testing are automatically linked to our database, enabling a seamless analysis pro-cess. Additionally, the software features a Defect Heat Map that overlays historical defect images, allowing us to conduct in-depth analyses and quickly identify recurring issues.

4. Increased Efficiency:

The AI-based system is designed for rapid deployment, with model training completed in short period of time, requiring minimal human oversight. Once trained, the system evaluates each cell efficiently and auton-omously, enabling us to maintain 24/7 operations without compromising on quality.

At REC, we are proud to lead the way in solar manufacturing innovation.

The successful integration of advanced AI technology into our EL testing process underlines our commitment to continuous improvement and our relentless endeavour to deliver the highest quality solar cells to our customers. The implementation of DENKweit`s AI-based EL image analysis software has led to remarkable results:

Exceptional accuracy

The system's high accuracy has significantly reduced false positives and negatives, ensuring that only the highest quality cells advance through our production process.

Informed Decision-Making:

The customizable classifications and detailed defect analysis empower our team to make better-informed decisions about cell quality, reducing waste and enhancing overall product quality.

Operational Excellence:

The efficiency gains from the faster evaluation times and automated analysis have allowed us to scale production while maintaining our commitment to quality.