Process optimization at Schüller kitchens

AI-based pore detection at Schüller Kitchens

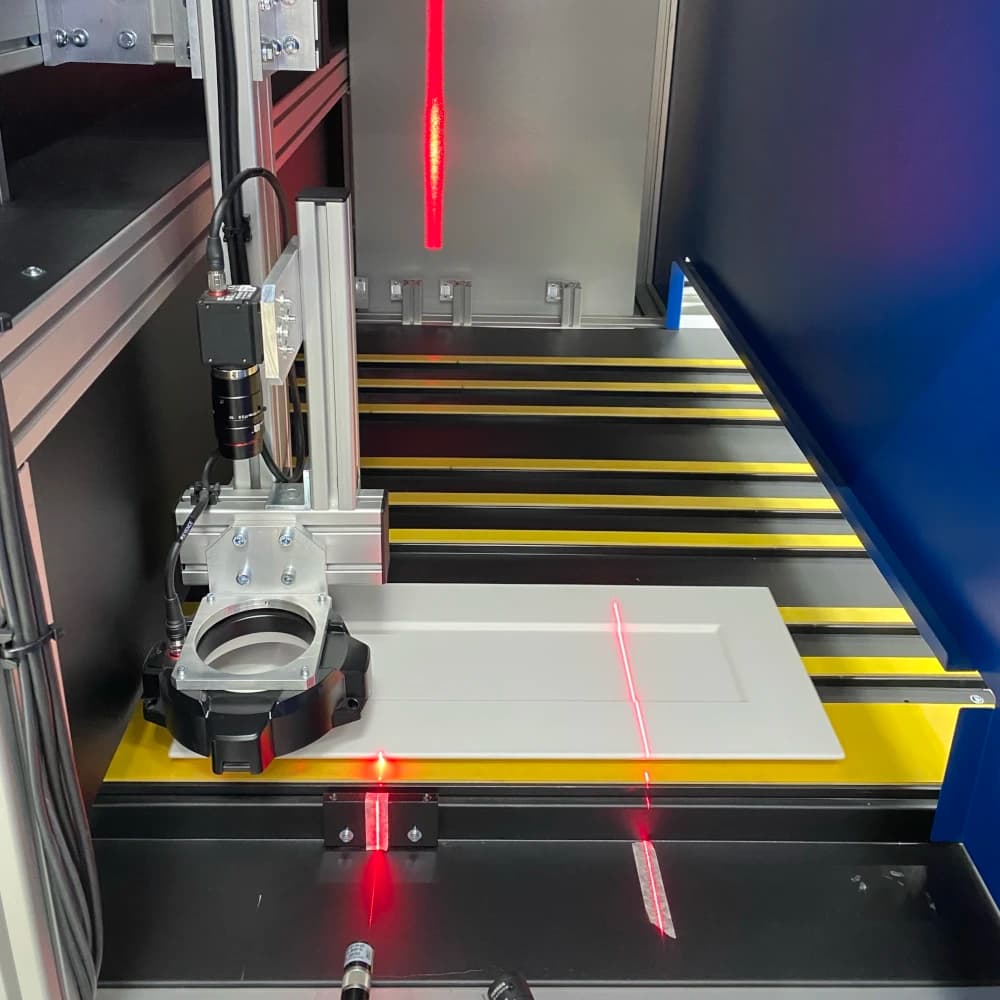

Highest precision in the production and quality assurance process by thinking

Around 60 years of experience and success

DENKnet as part of the success story

"Schüller. Kitchens for life" is the name of the company's slogan from Middle Franconia, Germany. Since 1966, kitchens "the highest quality, individuality and everyday suitability" have been built there.700 to 800 kitchens are produced a day, over 35 countries are supplied worldly, the number of employees is growing steadily.So that this continues to stay that way, the company steadily optimizes its production processes. Therefore, the system, in which components are identified, has now been equipped with image evaluation AI.

Identification of components

Goal: reduce error rate

Each component is assigned to a customer and is, e.g. for painting, briefly outsourced. After that, the component must be correct again be identified and assigned. This task was previously through complex, manual measurement of the individual component realized. This step should now be more efficient, namely automated, from State.

AI-based pore recognition

The identification of a component must be based on color -independent criteria take place. Another criterion is the grain, which also after a painting is recognizable. The company initially tried the To solve the task using classic algorithms and other providers. However, the experiments were very much with error rates between 7 and 1 percent unsatisfactory. After all, the company turned to thinking. The first test pictures already showed that the company neither with an error rate of 7% still has to be satisfied with 1%. The automated Pore recognition by DENKnet was directly during the regular Production process realized with an error rate of only 0.1%.

Pore structure or smooth front?

Challenge: Contrasts of deep black surfaces

Image on the left: pore structure.

Image on the left: pore structure. Image right: front without pore.

Image right: front without pore.A distinction, whether it is a smooth structure or a pore structure, must be reliably reliable in all colors (also black).

According to this, corresponding AI training over all colors and fronts was necessary. After training with only 720 pictures, Schüller already used a reliable AI. The "Classification" technology is used because the position of the pores are irrelevant for the company.

Integration into the existing system

The DENK Vision AI could easily be integrated into the existing system without making structural changes or extensions to lighting technology etc. Only a graphics card had to be used to use the full AI performance and evaluation every second.

Before, afterwards

Before using the thinking: Use of external AI: In 3 days, around 12,000 components were assigned incorrectly, which then had to be sorted manually. Error rate> 1%. With the use of a thinking: In 3 days, only 13 of 12,000 components were assigned incorrectly. Error rate 0.1 %.

Pore recognition with error rate <0.1%

Schüller was able to train and perfect the AI Hub himself in the Denkt Vision Ai Hub. They found that a color in AI training was particularly neglected, which led to the false recognition of the 13 parts. They added to pictures of those components and trained the AI with it. Result: Pore recognition with an error rate <0.1%.The company saves time and thus financial correction effort as well as complaint costs.