Saint-Gobain Weber – the Landsberg production site focuses on precision and efficiency

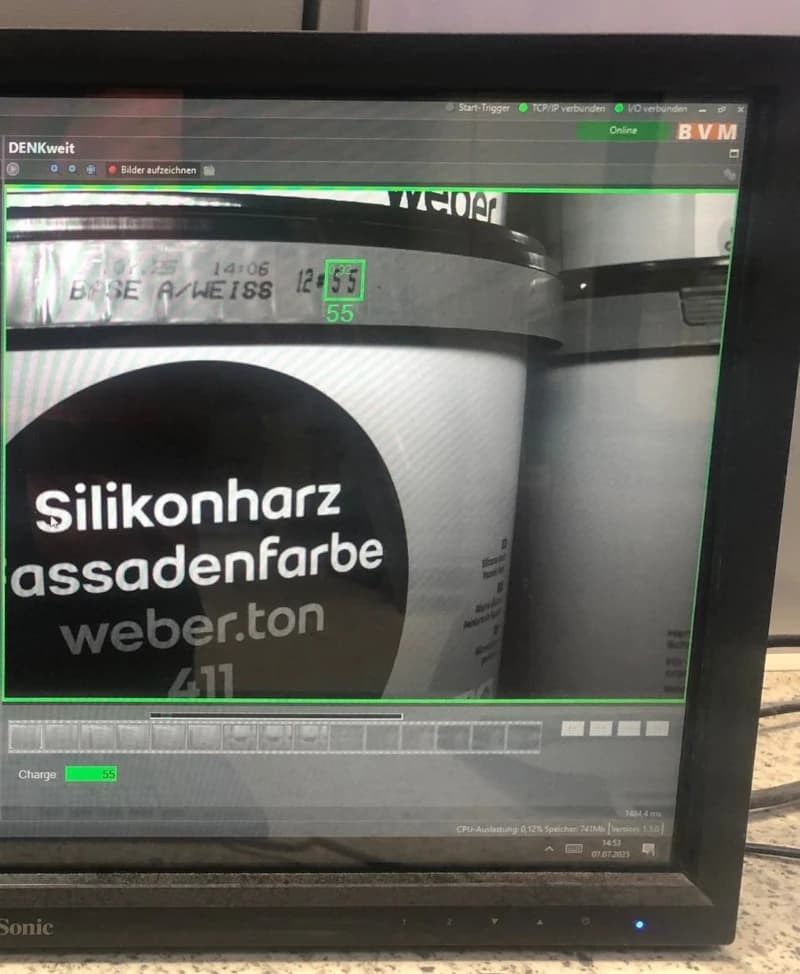

Automated labelling of canisters and bucket goods

Vision AI for smooth material flow

The plant in Landsberg has been in operation for over 30 years.

Since 2025, the company has been relying on Vision AI from DENKweit.

Saint-Gobain Weber GmbH is one of Germany`s leading manufacturers of building materials, offering over 800 premium solutions in the areas of plaster and facade systems, fleece and flooring systems, as well as building protection and mortar systems. Weber has 13 regional production sites in Germany, enabling it to respond quickly to customer needs.

Challenge: 150 different products

Variability meets process speed

Around 150 different product variants leave the factory every day, filled into buckets, canisters or large containers. The individual pallets are protected with stretch hoods and then labelled. To ensure quality and traceability, each product bears a unique batch number. But how can this information be recorded automatically when the container shape, label position and print colour are constantly changing?

Weber was already using an AI solution for product identification before collaborating with DENKweit. However, the 80% success rate achieved with the previous solution was unacceptable for the company, as manual corrections were time-consuming. Errors occurred mainly when container or coding colours changed, as well as when the arrangement of the batch coding changed – depending on the type of container (5-litre canister, 20-litre canister, bucket, etc.), the position of the batch coding changes. The previous solution, based on classic image processing, was not robust enough and the material flow came to a standstill.

With the use of DENKnet, reliable detection is now possible – regardless of the colour or orientation of the lettering.

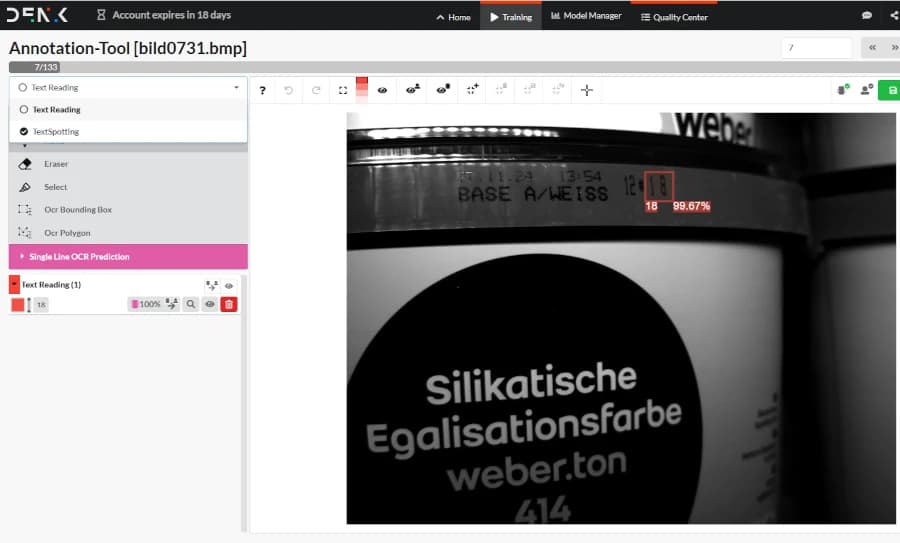

The solution: AI-based object recognition and OCR with DENKnet

Additional lighting was not necessary.

Together with the local implementation partner (Eric Marienberg and Dirk Heppner from Bildverarbeitung Marienberg GmbH), Weber selected DENKnet, the AI image analysis platform from DENKweit, for use in the project. The goal: to automatically, reliably and robustly recognise the correct batch numbers – regardless of which product they are attached to and where they are located.

The implementation was carried out using existing components: the camera system and labeller were already installed. An industrial PC (IPC) with a 5 MP camera connection was added, which runs both DENKnet and existing software processes. No additional lighting was required. The integration of the interfaces was carried out by Mr Marienberg.

The factory benefits from fewer manual interventions and backlogs.

A win for material flow, efficiency and quality.

Training, performance & results

Approximately 100 sample images were sufficient for AI training to optimise DENKweit`s pre-trained OCR so that it can recognise batch numbers on a wide variety of containers within milliseconds – even with changing printing colours and positions. Retraining and adaptation to new products is possible at any time via SG Weber Landsberg in the DENK VISION AI Hub.

Smooth material flow – without manual reworking

The recognition rate is already over 98%, with further fine-tuning taking place during operation. With the new solution, SG Weber has been able to fully automate image evaluation. The correct batch number is captured directly from the packaging and transferred to the labeller.

Long-term stability

The AI-based solution with DENKnet achieves exactly what traditional systems could not: robust, adaptive image analysis that flexibly adapts to new products and packaging scenarios. The example from Weber Werk Landsberg shows how targeted use of AI can not only automate production processes, but also stabilise and scale them in the long term.